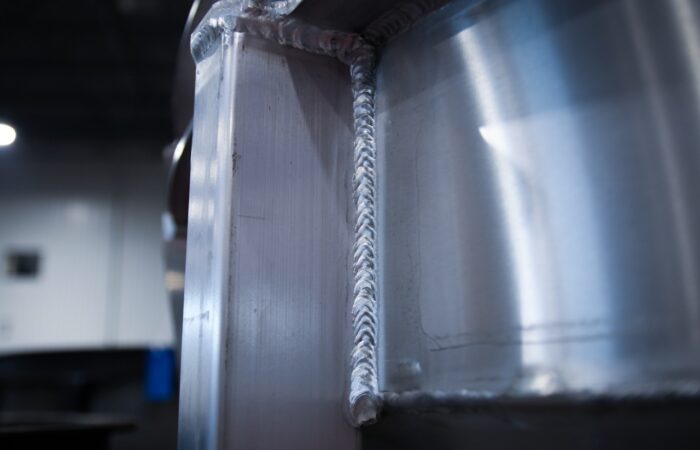

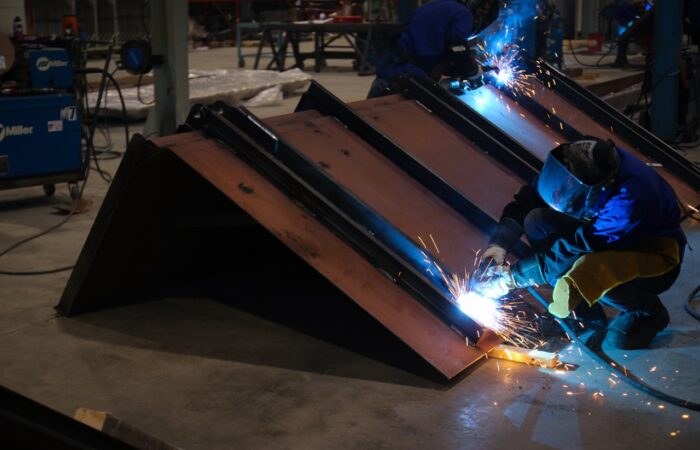

MIG/TIG Welding and Metal Assembly for OEMs

Our certified industrial welding service is designed for OEMs looking for a reliable partner for the repetitive assembly of metal parts.

We master MIG and TIG processes with a team of over 20 qualified welders, all certified under CWB (W47.1 / W47.2).

We deliver robust subassemblies that meet your technical specifications, with full traceability — even for ongoing production series.

Welding Capabilities

MIG/MAG Welding

Ideal for metal structures, frames, bases, and chassis

Materials: Hardox, Dual, HRPO

Stainless steel (304, 308)

Aluminum (4043, 5253, 6061-T6)

Precision TIG Welding

For fine assemblies, visible welds, and functional prototypes

HRPO and Dual steels

Stainless steel (308, 307)

Aluminum and light alloys (5000 and 6000 series)

Available Quality Controls

Visual inspection, dye penetrant testing, magnetic particle inspection

Compliance reports are available on request

Atelier outillé

Overhead cranes, welding tables, and custom jigs

Electrochemical cleaning station (for stainless steel passivation)

Welded Assemblies We Produce

We produce complex welded assemblies in series, ready for direct integration into OEM equipment:

Machine frames, articulated arms, and support plates

Welded chassis for vehicles or trailers

Tubular structures for industrial equipment

Subassemblies destined for final assembly at the client’s site

Why Weld with Plate 2000 Fabrication

Support, throughout the manufacture of the project

Stable, skilled team of certified welders

Full integration with laser cutting, bending, rolling, forming, and painting

Compliance checks at every production step

Ideal for repetitive production and planned workflows

Certified: CWB – ISO 9001:2015

Industries We Serve

OEMs use our welding services in the following sectors:

Agricultural Equipment

Forestry

Medical

Looking for a Reliable Welding Partner?

Trust Plate 2000 Fabrication for certified metal assemblies, delivered on time with consistent quality.