Precision CNC Machining for Industrial OEMs

At Plate 2000 Fabrication, our CNC machining service complements our metal fabrication operations to ensure the final finish or dimensional refinement of your parts.

We work with North American OEMs looking for a partner capable of consistently machining high-precision parts in series and on schedule.

Our approach is built on consistency, compliance, and long-term planning.

Our CNC Machining Capabilities

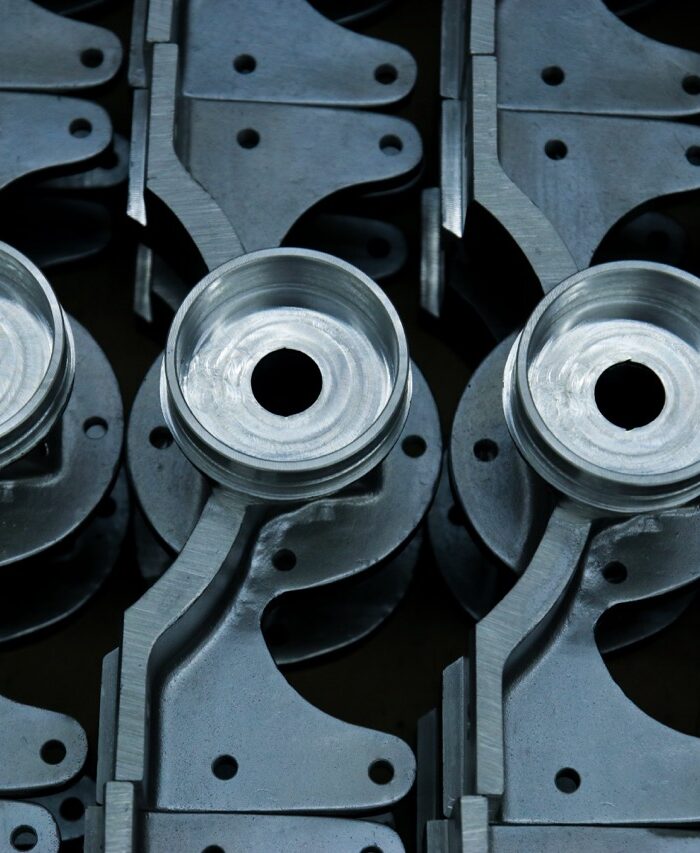

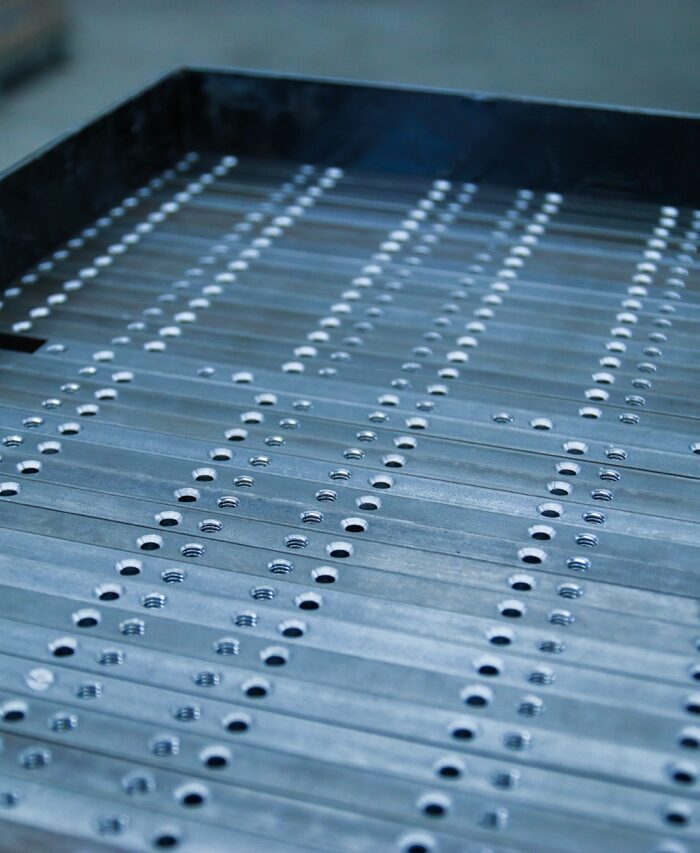

CNC Turning and Milling

High-precision machining of steel, stainless steel, aluminum, and hardened steel

Operations include drilling, chamfering, milling, threading, boring

Optimal repeatability for small and medium-sized runs

Post-Fabrication Secondary Operations

Machining after bending or welding

Adjustment of holes or functional surfaces

Precision work on critical zones for final assembly

Integrated Quality Control

Dimensional inspection and control jigs

Compliance with customer tolerances

Types of Machined Parts

We handle parts requiring partial or complete machining as part of scheduled repetitive production, including:

Machined base plates

Housings or brackets with aligned holes

Flanges, spacers, and machined bearing faces

Welded assemblies adjusted via machining

Functional components integrated into your systems

Why Choose Plate 2000 Fabrication for CNC Machining

Integrated machining within a complete production flow

Coordination with cutting, bending, welding, and rolling

Guaranteed tolerances and repeatability

Optimized lead times through long-term planning

Quality control is applied to every batch

Industries We Serve

Our machining services are aligned with the needs of OEMs in the following sectors:

Looking for a CNC Machining Partner for Your Metal Parts?

Rely on us for the machining of your metal parts with the peace of mind that comes with an integrated, stable, and repeatable service.